Group key figures

Our organic amendments and fertilizers are produced with raw materials of animal origin(manure, droppings..) and vegetable oriigin (vegetable waste, pruning wood …)produced and consumed locally in order to promote the circular economy and limitthe carbon footprint .

Elephant Vert,having an awareness of the necessary progression of organic agriculture, is able to increase its production on all its sites to meet the local and international demand.

Our sites , our production process and our raw materials are subject to regular controls and checks to ensure that they comply with the best production standards.

All our products are developed to be suitable for organic farming and can also be integrated into conventional farming .

The advantages of

EV industrial processes

Integrated maintenance for increased reactivity

In planta trials for continuous improvement

Mastery of technological processes

Know-how on the conservation of strains

Production of organic fertilizers and soil improvers

The Elephant Vert group has 3 main sources of production in biosolutions The biotech site of Meknes in Morocco delivers biocontrol products and biostimulants. The Kambiti site in Kenya industrializes the HELITEC product. The French subsidiary bio3g is specialized in liquid biostimulants.

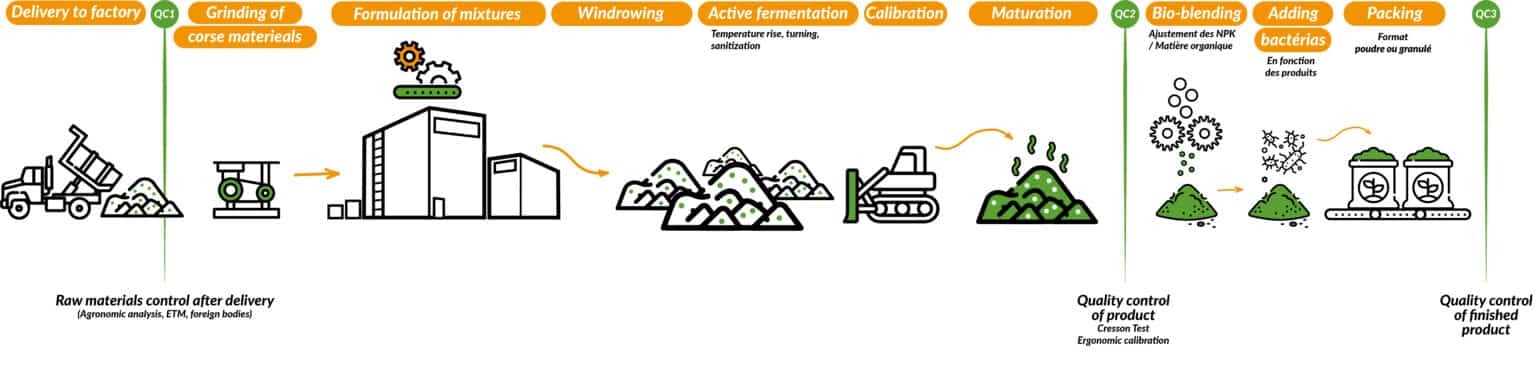

The manufacture of our organic amendments and biofertilizers goes through a natural biological process allowing both, the destruction of pathogens and weed seeds, as well as the stabilization of organic matter. These good composting practices guarantee the availability of products to farmers that are stable over time in terms of organoleptic properties and agronomic value.

Our products at the end of the process, and according to the need of the farmers, are mixed with stimulants, fertilizing bacteria or materials of adjustment of the elements N-P-K major fertilizers to provide a multitude of choices depending on the need of the crop being grown.

In addition to the controlled manufacturing process, our factories, such as the one in Meknes for example, areCertified Organic (for exporters to Europe) and NOP (for exporters to the USA).. This reinforces the positioning of our products in the market.

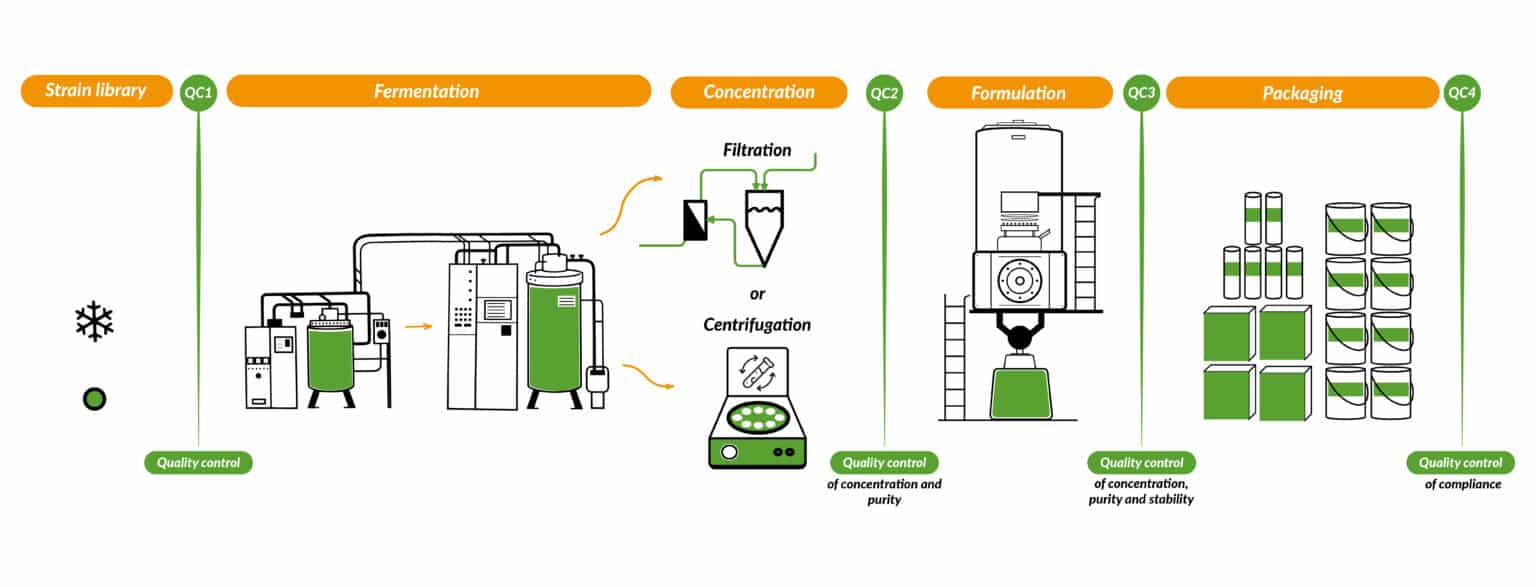

The production of biosolutions

The Éléphant Vert group has 3 main sources of production of biosolutions. The MEKNEs site in Morocco delivers products of biocontrol and biostimulants. The Kambiti site in Kenya works on the design of traps and lures (viruses). The subsidiary French company BIO3G is specialized in liquid biostimulants.

Generally speaking, the production process goes through several stages.. First, the strains are stored in the R&D laboratories, which guarantee the preservation and maintenance of the stock bank. Then, they are multiplied in liquid fermenters from 200 to 2000 liters, in controlled abiotic parameters.

A new phase begins which consists in obtaining spores resistant to environmental conditions (UV, temperature, drought...). This requires the use of solid substrates of agricultural origin (cereals) which must be sterilized beforehand. The development of the spores follows a conventional fermentation process. The spores are harvested by a solid/solid extraction system in order not to degrade their properties.

Eléphant Vert has the double expertise of fermentation in liquid medium and fermentation in solid medium. Consequently, the main equipment consists of fermenters of different sizes: small 200 l and large 2000 l.. Other equipment completes this manufacturing process, for example in Meknes: a100% automatic CIP station, a300 liter make-up tank (PH or Feed), a completeloading skid, water production and treatment units, and finally boilers and compressors.

Quality control of organic amendments and fertilizers

We guarantee the quality of our products to meet the needs of farmers and provide them with organic alternatives that respect the environment. During the entire production process, we ensure a strict quality control process along the entire value chain, from the control of raw materials to the finished product. We work in accordance with normative specifications, to guarantee hygienic products of better agronomic quality.

Created in 2016,our analysis and quality control laboratory is a physicochemical analysis laboratory inthe agronomic and environmental field, with a qualified technical team.. It makes it possible to support farmers in a reasoned fertilization process.

Accrédited bySEMAC (Moroccan Accreditation Body) for the realization of services in in the field of physico-chemical analyses on soils, waters and organic amendments, it is also recognized by ONNSA to carry out physico-chemical hydric analyses (Water of the food-processing industry and of breeding .

- 2016 : Creation of LACQ to support the development of ÉLÉPHANT VERT's activity and to carry out analyses for internal clients

- 2017: Opening of LACQ to the external market and marketing of various analytical services

- 2018: Obtaining the approval of the Ministry of Agriculture, Maritime Fishing, Rural Development and Water and Forests

- 2019: Obtaining ISO 17025 V2005 accreditation for water and soil matrices

- 2020: Extension of accreditation on the AMEO matrix (organic amendment and culture medium) and migration to ISO 17025 V2018

- 2021 : Obtaining the recognition of the National Office of Sanitary Safety of the Food products ONSSA to carry out the physico-chemical hydric analyses.

An adapted product

and service offer

For 10 years, EV has structured a complete offer that can be used mainly in organic farming to improve the quality and yield of crops while respecting farmers and the soil.

EV Stim, the range of soil and foliar biostimulants which stimulate plants and help them grow, feed and better tolerate environmental stress.

EV Protect, uses its biocontrol range to protect crops against pests and diseases and strengthen the plants’ ability to defend itself.

EV Nutri, uses its nutritional range to enhance the soil and feed plants, composed of organic amendments along with fertilizers and deficiency correctors.

EV VALO, the range of services to provide customized solutions to farmers and distributors through training and analysis of plants, water, soil and residues.

AMEO manufacturing process

An example of biostimulant production

Business experts

In charge of the Quality Control in Meknes

In charge of the Kambiti virus production site

In charge of the composting platform in Segou

In charge of the Ross Bethio composting platform

In charge of the group's Biotech production sites

In charge of tMeknes' Biotech production site