Key figures

of projects

partnerships

For 10 years, EV has positioned itself as a“pure-player” in biosolutionsand has based its expertise on the development of biostimulation andbiocontrolproducts.

Éléphant Vert specializes in the development of products created from natural active ingredients derived from biotechnology (extracts or micro-organisms derived from biodiversity).

The group's R&D is organized around bio3g's quality and r&d laboratory in Merdrignac, specialized in biofertilizers, biostimulants and agronomy, and lipofabrik's r&d biotech laboratory in Lille, specialized in molecular biology, process engineering and formulation, as well as a team dedicated to the application of product prototypes in real field conditions..

The active substances we develop are naturally present in nature.. We rely on our expertise in fermentation in liquid and solid media to develop effective biosolutions that respect the environment and people.

EV benefits from an ecosystem of expertise with 60% of our projects carried out in partnership with public or private research laboratories.

Lipofabrik , winner of the 2021 France Recovery Plan,is expanding its production capacity to a semi-industrial scale in order to accelerate product development.

Every year, our scientific advisors at Lipofabrik contribute to the writing of scientific articles in conjunction with their universities, but also with partner universities in order to disseminate and accelerate the development of biosolutions.

Eléphant Vert is also a member of various competitiveness clusters, working groups and associations aimed at accelerating research into biosolutions (Bioeconomy for Change, Biocontrol Consortium, Rittmo, AgriSudOuest, AgreenTechValley, etc.)

Our strengths

100% natural origin

10 years of r&d in biosolutions

more than 1700 strains in internal collection

a sustained relationship with the academic world

The selection

We evaluate the activity of natural active substances,in particular those of micro-organism strains and the compounds they can produce (microbial metabolites). The genetic profile of the strains of interest is first studied by bioinformatics tools.. The strains with genetic capacities to synthesize potentially interesting metabolites are then tested for their efficiency and their impact spectrum against different pathogens of interest.

The metabolic study of active molecules relies on state-of-the-art analytical chemistry skills and equipment (LC-MS, GC-MS, UPLC, HPLC, MALDI-TOF...) to identify and monitor the production of these compounds.

The identified strains are put in an internal collection and the most promising ones are deposited in the Collection Nationale De Cultures De Microorganismes (CNCM) of the Institut Pasteur.

The micro-organism that has proven its potential activities as a biostimulant or biocontrol is optimized at the laboratory scale through the implementation of high-density screening adapted to robotic equipment allowing us to analyze more than 5000 strains per day.

Optimization is then done by improving the culture conditions. Thanks to modern technological tools, it is possible to test up to 48 different conditions simultaneously, while continuously measuring different parameters. Work on the strains can also lead to an understanding of the mode of action.

The optimization step is important to validate the industrialization capacity of this product and to increase its production (biomass/metabolite).

Photo: "The colony picker (QPix 460), one of the many high-density systems on the realcat platform (University of Lille)"

Preparation

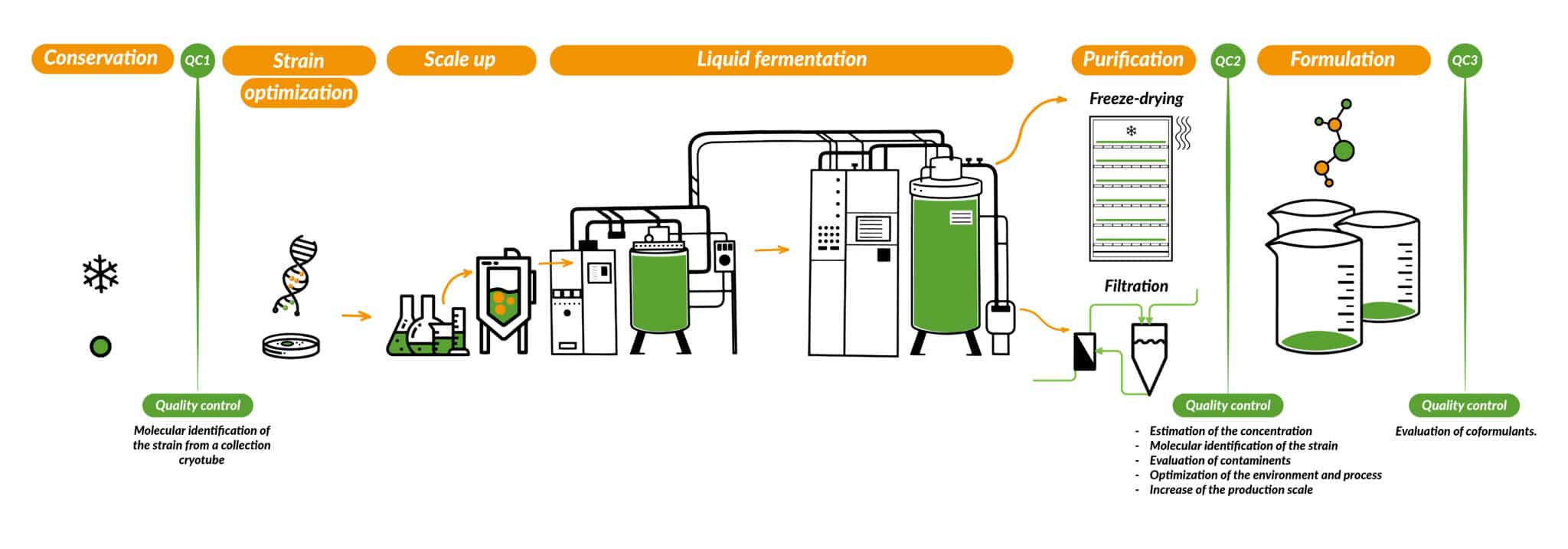

In order to allow production on an industrial scale, the optimization of the environment and culture conditions is a key step. This involves production in small fermenters to optimize the liquid fermentation phase, common to the production of bacteria, their metabolites and fungi. The parameters determined at this stage make it possible to increase the biomass of the micro-organisms or to favour the production of specific molecules of interest.

This optimization can be done for a production by bringing the culture medium in one time (batch) or continuously ( fedbatch ).

At the end of fermentation, the microorganisms and metabolites are mixed in the culture medium and the active substance must be isolated. This can be done, for example, by centrifugation, filtration, freeze-drying etc. The expertise of EV allows us to make the most efficient choices to obtain the live microorganism or the purified metabolite according to the needs.

State-of-the-art analytical equipment allows the monitoring of fermentation and media depletion, as well as the identification and quantification of primary and secondary metabolites in the final product and during intermediate steps. Analysis of the purified product also allows allows the determination of its final purity and the calculation of yields. HPLC machines are used (high pressure liquid chromatography), and UPLC (ultra-high pressure liquid chromatography)

Formulation is a key step to make the active substance available by ensuring, among other things, its solubility and adhesion to the targeted parts of the plant. This step is based on physicochemical and biological knowledge of the active substance and on the knowledge of the co-formulants that can be used to optimize the properties of the finished product.

Evaluation

After initial in vitro evaluations and laboratory scale productions, candidate strains are evaluated under controlled conditions on plants. The conditions are carefully chosen to allow the best definition of the potential of the active substance These first steps on the plant allow a first work on the dose, the application method and thepreliminary evaluation of the formulations. It also allows us to identify possible risks of phytotoxicity.

Validation and optimization of the effectiveness of active substances and formulated products under real conditions is a critical phase in the development of biosolutions,the robustness of their effectiveness being one of the main expectations for these products. Through its network of partners and service providers, Éléphant Vert sets up agronomic trials very early in the development of its products in order to best negotiate this stage of the development of biosolutions.

Once their potential in terms of efficacy and productivity has been validated, the selected active substances are subject to specific bibliographic and experimental studies to understand their mode of action. This allows an understanding of the active substance, and for our biocontrol to identify possible risks of the effects on organisms or the development of resistance in target organisms.

In addition, understanding the mode of action of active substances is a lever of interest for optimizing application conditions.. This work is based on skills in microbiology and plant/microorganism interactions, but also in entomology and phytopathology.

Testing

In parallel with optimized laboratory-scale production, work on scaling up production is being carried out to all ow a gradual transition from laboratory to a semi-industrial scale. A 300L pilot fermenter is used as an intermediate scale, and a line consisting of 2 tanks of m3 as well as a packaging line have been integrated.

In parallel with the scaling up, the preparation of registration dossiers involves the performance of numerous tests, including validation of the absence of toxicity and the ecotoxicity of active substances and formulated products. These dossiers are being prepared progressively, drawing on the expertise of the group's regulatory department.

An example of the development process

of a Biostimulant product

Molecular biology

Doctor, Expertise in genetic optimization of Bacillus subtilis and in lipopeptides.

Molecular biology

Expertise in plant, microbiological & analytical biotechnologies.

Molecular biology

Expertise in molecular and cellular engineering and screening of mutagenesis-derived strains.

Molecular biology

Expertise in molecular and cellular engineering.

Fermentation

Expert in Fermentation.

Fermentation

Expertise in microorganism fermentation.

Fermentation

Expertise in fermentation, process improvement and industrial scale production.

Purification

Expertise in purification techniques for liquid biological products.

Formulation

Expertise in formulation applied to agriculture and health.

Tests - Applications

Specialized in agronomic evaluations.

Tests - Applications

Specialized in evaluation under controlled conditions.

Tests - Applications

Specialized in microorganisms / plants interactions.

Microbiology

Doctor in biotechnology.

Microbiology

President of the TERRA research and teaching center. Professor of microbiology and applied microbiology.

Microbiology

Advisor,Professor of biotechnology and microbiology.

An adapted product

and service offer

For 10 years, EV has structured a complete offer that can be used mainly in organic farming to improve the quality and yield of crops while respecting farmers and the soil.

EV Stim, the range of soil and foliar biostimulants which stimulate plants and help them grow, feed and better tolerate environmental stress.

EV Protect, uses its biocontrol range to protect crops against pests and diseases and strengthen the plants’ ability to defend itself.

EV Nutri, uses its nutritional range to enhance the soil and feed plants, composed of organic amendments along with fertilizers and deficiency correctors.

EV VALO, the range of services to provide customized solutions to farmers and distributors through training and analysis of plants, water, soil and residues.