Following an interview with our Director of Innovation and Products, France Thevenieau, Neftys, the first fintech specialized in the pre-financing of research and innovation tax credits, published an article on its website about EV.

For ten years, Eléphant Vert has been developing biosolutions for sustainable and responsible agriculture.

Occupying nearly two thirds of the French territory, agriculture has a major responsibility in the management of natural resources and the living heritage that constitutes its primary resource. Minister of Agriculture and Food under the first term of Emmanuel Macron, Didier Guillaume, now a Senator, wrote in 2019 that “ **The future of our agriculture depends on an even higher level of requirement in production, with fewer pesticides, optimized water management, redoubled attention to animal welfare.”

This is exactly the mission that Eléphant Vert set itself ten years ago, by developing and marketing agricultural biosolutions.

Meeting with France Thevenieau, Director of Innovation & Products, to understand the will and the means of action deployed by an innovative actor to accompany the world agriculture in its ecological transition.

Today present on several continents, the company is the result of an initiative with a mission

At a time when immediacy has become the norm for digital companies, we tend to forget that the ambition and impact of a project can sometimes be measured by the time it takes to develop it. This is precisely the case of Eléphant Vert, a company that was created ten years ago with the aim of changing agricultural practices.

The company’s objective is as follows: to improve agricultural productivity in a sustainable way thanks to organic products, which constitute an alternative to conventional products (phytosanitary products). “The specificity of Eléphant Vert is that we are a pure player in biosolutions“, explains the person in charge of the product innovation division. “This is a strong choice, because most of our competitors often market a combination of conventional chemicals and biological alternatives“she says.

And she reminds us that despite the company’s mission-driven DNA, Eléphant Vert remains first and foremost a commercial company. Its 900 employees are divided into two main activities: on the one hand, the sale of products directly, via subsidiaries, to farmers; on the other hand, indirect sales via local distributors. The group is present throughout the world: there are Eléphant Vert subsidiaries in Africa (in Morocco, Mali, Ivory Coast, Senegal, Kenya and Tanzania) as well as in Europe (in France, Belgium and Switzerland).

The production of micro-organisms: a real obstacle course

How does Eléphant Vert help farmers in concrete terms? By producing three types of solutions: first of all, organic amendments and fertilizers, produced locally. “The term “soil improver” is used to designate anything that is derived from organic matter that undergoes a large-scale natural fermentation process, with the aim of being able to provide a contribution (in nitrogen, phosphate, etc.) to the plant in order to boost its productivity“explains France Thevenieau. Biofertilizers follow the same principle as soil improvers, with targeted inputs of nitrogen, iron, etc.

In addition to these locally produced products, Eléphant Vert is also developing two other types of products in laboratories. On the one hand, biostimulants, which will stimulate the growth of the plant, its resistance to water or biotic stress, and which are of natural origin. On the other hand, biocontrols, which allow to protect plants against various aggressions. We find for example in this category insecticides, organic or biological. Within the category of biocontrols, we find macro-organisms (eg ladybugs), pheromones (which attract predators to better trap them), microorganisms and plant extracts. Eléphant Vert specializes in the production of microorganisms and molecules produced by these microorganisms.

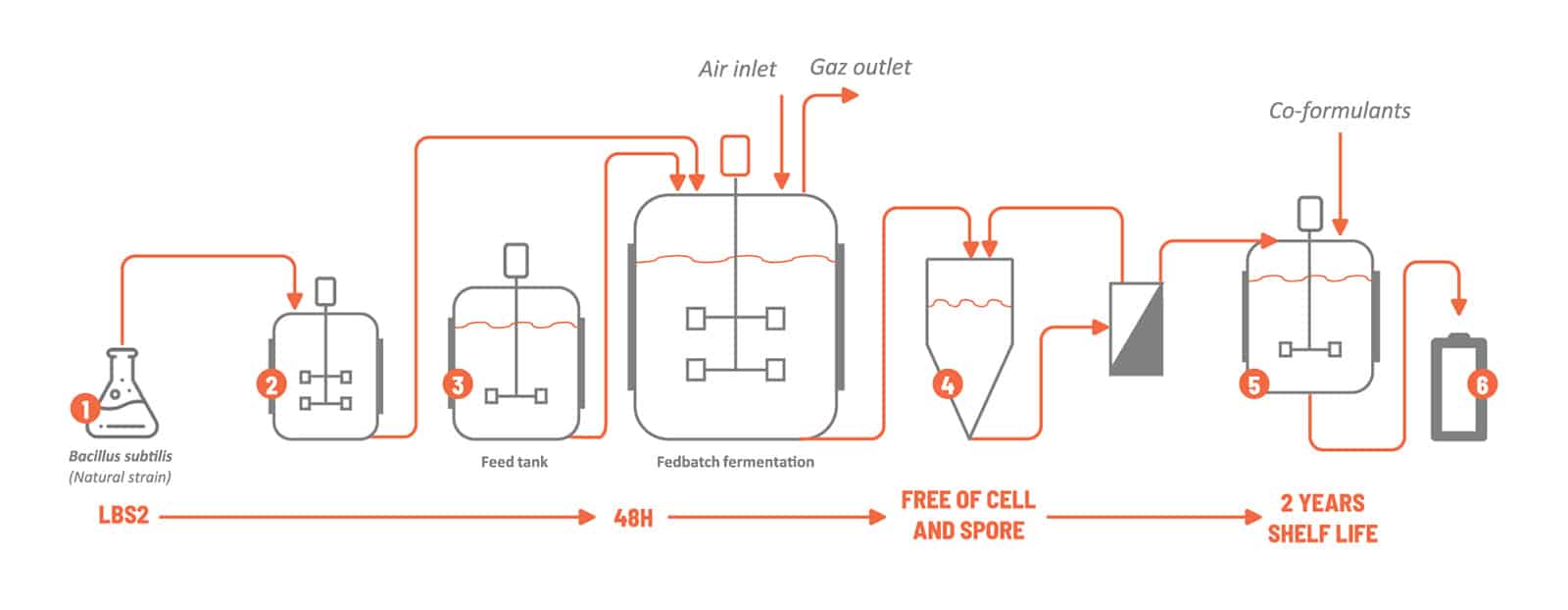

To understand the extent of the expertise of France Thevenieau’s teams, let’s focus on the process of creating biocontrols from microorganisms. An important clarification first: microorganisms exist in nature, they do not result from any chemical synthesis. Therefore, the origin of the molecules developed by Eléphant Vert is necessarily natural. Among the technical processes used by the teams, France Thevenieau mentions fermentation in liquid medium (as used by breweries), and fermentation in solid medium, where raw materials such as rice or other agricultural materials are used to produce microfungi.

What are the major steps in the production process? Once the microorganism has been identified and tested, a biocontrol product must be developed from it. This relies on Eléphant Vert’s in-house ability to formulate the product so that it is as effective as possible on the target. Finally, all the tests required by the registration file must be carried out, i.e., the impact of the product on the environment and on humans must be verified. To carry out these different tasks, Eléphant Vert relies on three major areas of expertise: its formulation capacity, to ensure that the product is relevant and adapted to farmers’ practices, its production industrialization capacity, to produce the molecule on a large scale, and its regulatory know-how. Product registration is a long and costly process – the average time to develop a biocontrol product is 8 years!

Partnering for Speed

Despite its extensive in-house expertise, the company does not hesitate to enter into partnerships. “At our level, we don’t do basic research,” says France Thevenieau. Instead, the company forms partnerships with universities, startups or other private companies (sometimes even competitors) with whom it joins forces to develop a project. The starting point for each new project is a laboratory proof of concept. For Eléphant Vert to decide to develop a new product, the POC must have shown its efficacy on the plant, in vitro or in planta; the active substance contained in the microorganism must also be characterized, to see if it is innovative.

“Once we are convinced of the potential of the active substance and its efficacy, we set up the partnership,” says the innovation and product manager. In particular, her teams are doing a lot of work in terms of preliminary tests on the toxicity aspect, to make sure that the product will be labeled low risk by European regulations. Once these toxicity and efficacy tests are completed, Eléphant Vert begins the studies required for the registration file, a long and costly process. It is to reduce the heaviness of this kind of process that a company like Eléphant Vert sometimes chooses to collaborate with startups. “These startups often have neither the expertise nor the financial capacity to support the creation of these certification files,” acknowledges France Thevenieau.

Last February, Eléphant Vert acquired the Lille-based startup Lipofabrik, with which it had already been working for three years. Thanks to its expertise in research and development of biosolutions, Lipofabrik has developed a unique biostimulant on the market based on Bacillus subtilis, named PlantBoost. Tests on this product have been conclusive: they have shown remarkable and constant increases in biomass, harvest and fruit quality. Beyond the PlantBoost product, the combination of the two companies will allow Eléphant Vert to expand its portfolio of biofungicide biocontrol products. France Thevenieau highlights the complementarities between the two companies in terms of R&D, industrial, biotech, marketing and sales.

Complementarity of means and similarity of vision: “We are driven by a common objective, that of developing and bringing to market biocontrol products that will serve sustainable agriculture“, concludes the Director of Innovation & Products. The company’s leitmotiv could be: produce better and grow differently, i.e. naturally and efficiently.